Stability of

Emulsion :

A stable emulsion may be defined as one in which the

disperse phase retain their initial character and remain uniformly distributed

throughout the continues phase.

Stability may be defined in term of physical and chemical stability.

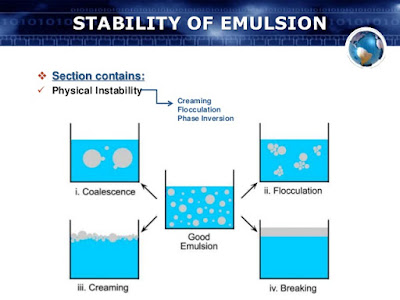

Physical Stability: Physical stability is that type of stability of emulsions

which is associated with the physical characters of emulsions. It may be due to

creaming, aggregation or flocculation, coalescence and inversion.

Creaming and Sedimentation : Creaming is due to the upward

movement of disperse phase. Creaming leads to coalescence and breakage of

emulsion. Creaming occur when the density of disperse phase is less then the

continues phase. Creaming is reversible phenomenon and can be easily reversed

by mechanical agitation for a shorter time.

Disadvantages of Creaming:

1) it leads to inelegant emulsion.

2) Dose disturbances may

occur.

3) creaming may cause coalescence and further breakage of emulsion.

Remedy: Stocks

law define remedies both for creaming and sedimentation. Stokes law

V2=d2∆Ꝿ g/18η

D2 is the diameter of the globules reducing the

diameter of the globules V (velocity) of creaming will decrease and thus lesser

chance for creaming. Small particle size of disperse phase lesser the chances

of creaming.

∆Ꝿ is the difference between the density of

disperse phase and disperse medium. Higher the difference the greater will be

the chance of creaming.

g is the gravitational velocity.

η is viscosity------- increasing the viscosity

creaming chances will be reduced. Viscosity can be increased by adding

viscosity builders like Methyl cellulose in O/W emulsion and addition of soft

paraffin in W/O emulsion. Storing the emulsion at low temperature (above the

freezing point ) increase the viscosity of emulsion thus lower the creaming

phenomenon.

Proper ratio

of Disperse phase to Disperse medium: One

approach to reduce creaming is to have proper ratio of Disperse phase to

disperse medium. The ratio of less then 20 % will readily lead to creaming. It

is theoretically possible to have disperse phase ratio up to 74 % but in

practically it is not more then 60% and some studies prefer 50% not more.

Flocculation:

Flocculation is the aggregation of globules

into a loose cluster. The globules retain their individual integrity but are

just in aggregated form. Flocculation enhance the chance of creaming and it is

the preceding step in coalescence. Flocculation is a reversible phenomenon and

can be disturbed by agitation.

Flocculation is an electrical phenomenon in which the globules stick

together due to some sort of attraction between them.

Remedy : By adding possible effective surfactants

possessing a suitable electric charge to prevent this phenomenon.

Coalescence:

Coalescence is the growth process in which

small particle/globules of disperse phase merge together and form a large

particle, which further merge and lead to separation of two phase (breaking).

As said causes of coalescence are creaming and flocculation. Both of these

precede the coalescence. Coalescence is the irreversible phenomenon. It is

differ from flocculation in irreversibility and integrity of particle (in

flocculation no merging occur) and another difference between is that

coalescence dose not depends on charge.

Reasons: coalescence occur when there is the breakage

of interfacial film of the emulsifiers around the dispersed globules.

Remedy: Coalescence can be overcome by adding Mix

emulsifying agents which give

1)Elastic and rigid film.

2) Viscous film (Elastic and viscous film reduces

the chances of Coalescence

3) cautious use of HLB scale for selection of

emulsifying agents.

Inversion

: Inversion is also one of the problem

with the emulsion. Inversion is the process in which o/w water emulsion turns

to w/o emulsion or vice versa. This phenomenon is due to

Temperature: high temperature may change the

characteristic of emulsifying agent thus promote phase inversion i.e polysorbates stabilized o/w emulsion is

inverted to w/o because of the breakage of H bonds in polysorbates due to

heat. Temperature at which inversion

occur is called phase inversion temperature (PIT).

Electrolyte addition: Sodium-oleate which

stabilize O/W emulsion when Calcium chloride is added to it turns to W/O

emulsion because calcium oleate is more soluble in oil.

Ratio of disperse phase to disperse medium:

using a high ration above 60 percent of dispersed phase inverses the emulsion.

Limit of disperse phase is 74 % which is

impractical.

Thanks for your superb post and selected article on your blog, We wishes that you offer some time with us.

ReplyDeleteYou are Welcome. That will be my pleasure

Deletegot lot of information by ths blog

ReplyDeleteprescription discount card online

Welcome

DeleteThis is My Pleasure Jhon Mac. You are Welcome

ReplyDeleteThanks for the detailed explanation!

ReplyDeleteThis really helps for my Pharmacist licence exam!

You are welcome dear

DeleteTq

ReplyDeleteGood explanation of the question

ReplyDelete